These are the genuine 'Momotaro Bakki Showers', and their amazing results have resulted in many expensive copies being made. Out Momotaro Bakki Showers are the only ones that use the 'Bacteria House' filter media, which incidentally, is where the secret lies! Accept no alternatives.

These are the genuine 'Momotaro Bakki Showers', and their amazing results have resulted in many expensive copies being made. Out Momotaro Bakki Showers are the only ones that use the 'Bacteria House' filter media, which incidentally, is where the secret lies! Accept no alternatives.

Bakki Showers are offered at two price points... 'Standard', or 'Premier', with various weir or chute options being available. These systems are of the same design shape, with the main difference between the two, being slightly simplified construction techniques on the cheaper system.

'Bakki Showers' and 'Bacteria House' are patented Worldwide by Momotaro Koi Farm. Our systems are the only ones made under license from Momotaro.

Because of the sheer expense of 'Bacteria House', we are doing our utmost to keep the Shower prices to a bare minimum, so that the overall package represents excellent value for money.

Please note. The system pictured above is a 'version 2' (discontinued March 2004 due to improvements made in areas of splashing and water distribution).

Bakki Shower prices start as follows:-

'Premier' 4 tier system with bottom exit £695

'Bacteria House' filter media (10kg box) £140

'Premier' package with 50kgs of Bacteria House media (saving £100 on system) £1295

Weir option on above, add £125

'Polycarb' insulation mounting brackets £35 set.

We are happy to sell three tier systems, but strongly recommend the use of four tiers, as it is essential that the water has the chance to increase in velocity between the four tiers. More tiers will give better results. We also strongly recommend sticking to the use of Bacteria House in these systems. Other medias will work to a degree in certain aspects, but only Bacteria House will work if these systems are used as the sole filtration.

|

All of our Bakki Showers are made in 316 food grade stainless steel. We have tried making cheaper plastic alternatives, but it has proved impossible to get a system that had the advantages of the Stainless steel models. The biggest problem we experienced with plastic, was that it was only viable to have a drilled bottom, which was prone to regular blocking and trapping of debris. So we have decided to stick solely to the stainless Bakki Showers. All of our Bakki Showers have an open square mesh bottom. These units are stamped out by computerised machinery, in such a way that the sides of the systems are integrated with the mesh, making them much stronger than they would be with a welded mesh. They are also fuse welded so that no metal is added to the welds. It is the computer cutting of the steel that results in the edges so be so accurately cut, that fuse welding is possible. This ensures that the welds won't rust like conventional stainless welds. Also, the nuts that are used to attach the support brackets, are pressed, not welded. We have paid great attention to detail with these systems, and spared no expense! |

|

|

|

The overall flaring of each tier of the Shower ensures that no water is spilled by the system (this was a minor problem with the discontinued 'version 2'), and also keeps the water tracking evenly through the media. The older systems used to allow water to track down the vertical sides of the system, hence missing some of the media by the time it got to the bottom tier. The flaring of the 'version 3' systems prevents this by making sure that as the water runs of the outer extremities of the system, it is thrown back directly onto the media in the next tier. There are endless options available for these systems, as well as bespoke units which can be made to suit your own application. Enclosure accessories are also available, for 'over-winter', or open air applications. | |

|

The pond on the right features two systems with the 'weir' option. These two systems are fed with water pumped directly from the bottom drains, with no settlement, or additional filtration. To find out more about how 'Bakki Showers' and 'Bacteria House' work, take a look at the next page. |

|

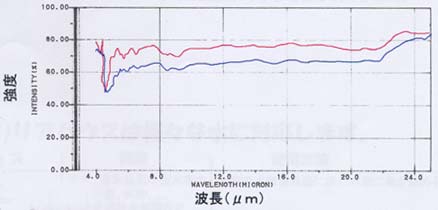

| Testing of 'Bacteria House' has been rigourously carried out, by both Momotaro, and MTK (manufacturer). Mr Manami (President of MTK) is a Koi hobbiest, and as such, built three ponds built to enable lab testing of endless 'blends' of Bacteria House, and other medias. Bacteria House in it's original form was originally made for treating effluent water, and won the accolade of "Best Filtration media in the World" three years ago. The 'blend' that Momotaro use however, is very different. Each tray of the Showers at MTK is split into 5 divisions. Each of these contains a different media. The pond testing is carried out by filling the ponds with Koi, and then maturing the systems. Periodically, a sample is taken from each media (60 types, most being differents 'blends' and forms of Bacteria House), and sent for lab analysis. The medias are tested to find which bacteria strains are present, and for bacterial counts. |  |

|

|

Momotaro tested every available media, submerged, and then in Bakki Showers. They weren't just looking for good water parameters, but also for the best growth, and quality of the Koi. Their findings were, that Bacteria House submerged, out performed all of the other medias. But, when Showered, Bacteria House came into it's own, as it gave even better results. They also found that Bacteria House media was the only media that worked in the Showers, and that every kind of plastic media that they tried, couldn't maintain a biomass in the Showered configuration. |

|

|

Daisuke Maeda once said to me, "Imagine you are sitting in a closed room, about to eat a delicious meal. If a cat came in the room, and went to the toilet in the corner, would you still feel like eating? Well, it's the same for Koi! If Koi can smell their own urine, they won't eat so well. This is why Koi have increased appetites when Bacteria House is used, particularly in Bakki Showers!" This is an inside view of one of the kilns at the MTK factory. This is similar to the ones used for firing Bacteria House, but is a lower temperature one, being heated to about 1100c. Bacteria House has to be fired in their hottest kiln at 1300c for 60 hrs, in order to make sure that it's surfaces explode, resulting in the millions of open cells, where the Bacteria multiply. This is an extremely expensive process, and limits the maximum production to 1.5 tons per day. Bacteria House is made from a careful mix of ingredients, which are blended together with the utmost care. The mixed raw product then comes out of an extrusion machine, where it is cut to length by two staff, and rolled in a special powder which prevents the pieces of Bacteria House from bonding together in the kiln. |

|

|

|

Bacteria House in the furnace, being fired. This furnace is about 40 feet long, and to be even as close as 10 feet from the furnace in virtually unbearable. If you have ever wondered why Bacteria House is so expensive, we hope you now understand why. In conclusion... people generally think that those bacteria that deal with pollutants, are the only ones needed for Koi, but there are really countless strains that make up the pond eco-system. It is of paramount importance to get the balance of those aerobic, and anaerobic bacterias right, if you want to make Koi blossom and grow healthily, rather than just simply keeping them alive. Please see our Appraisals page for information on how to use the Bakki Showers, and Bacteria House media. |